Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Thuis > PZT Materials

Lead Zirconate Titanate (PZT)`s attributes of producing an electrical charge when mechanically compressed or vibrating when an electrical charge is applied, make it very conducive for passive sensing, active transmitting and mechanical displacement applications.

We utilize two predominant types of piezoelectric materials, each providing a set of unique properties suitable for a range of applications. Two types of piezoelectric ceramics include High Power "Hard PZT" and high Sensitivity "Soft PZT".

High powder "Hard" Piezoelectric Materials are ceramics able to withstand high levels of electrical and mechanical stress and are particularly suited to high voltage and power applications.

High sensitivity "Soft" Piezoelectric Materials are particularly useful for sensing applications due to its high sensitivity and permittivity. As such these piezoelectric ceramics are frequently used in low power applications as transducers, receivers and generators.

PZT is a machinable ceramic and can be precision dimensioned into tubes, rings, discs, plates, and hemispheres. The PZT material is also versatile from a forming aspect as it can be net shaped by pressing, extruding and casting into these same shapes as well as complex components including, co-fired bimorphs and multilayer actuators. Sizes range from microns to centimeters. Electrode choices are extensive including fired silver, electroless nickel, sputtered or vacuum deposited Nickel-Chrome, Gold, Tin, Aluminium and Vanadium.

Hard PZT

High power or "hard PZT" ceramics can withstand high levels of electrical excitation and mechanical stress. These materials are suited for high voltage or high power generators and transducers.

PZT-4 Series

This material range is ideally suited for ultrasonic cleaning, sonar, and other high power acoustic radiation applications. These materials are designated as PZT-4 series type materials and are capable of producing large mechanical drive amplitudes while maintaining low mechanical and dielectric losses. In addition, it can be used under both constant and repetitive conditions. Within this group of materials, Yuhai offer a complete range of three PZT-4 series material types with a variety of permitivity values, coupling, power handling and actuation properties.

PZT-8 Series

This material range is used in high power applications, even though its piezoelectric activity level is slightly lower than PZT-4 series types. With an extremely high mechanical quality factor and extremely low loss factor, PZT-8 series materials have the ultimate power handling capability. Within this group of materials, Yuhai offer a complete range of three PZT-8 series material types with a variety of permittivity values, coupling, power handling and actuation properties.

The typical value of "Hard PZT" ceramic performance

| "Hard" PZT materials | ||||||||

| Properties | PZT-41 | PZT-42 | PZT-43 | PZT-82 | PCrN-4 | PBaS-4 | ||

| Dielectric Constant | ɛTr3 | 1050 | 1250 | 1420 | 1100 | 1600 | 1900 | |

| Coupling factor | KP | 0.58 | 0.58 | 0.58 | 0.52 | 0.6 | 0.59 | |

| K31 | 0.32 | 0.33 | 0.34 | 0.3 | 0.35 | 0.34 | ||

| K33 | 0.66 | 0.67 | 0.68 | 0.57 | 0.68 | 0.68 | ||

| Kt | 0.48 | 0.48 | 0.48 | 0.4 | 0.45 | 0.49 | ||

| Piezoelectric coefficient | d31 | 10-12m/v | -106 | -124 | -138 | -100 | -156 | -160 |

| d33 | 10-12m/v | 260 | 280 | 300 | 240 | 350 | 380 | |

| g31 | 10-3vm/n | -11.4 | -11.2 | -11 | -10.3 | -11 | -9.5 | |

| g33 | 10-3vm/n | 28 | 25.3 | 24 | 25 | 24.7 | 22.6 | |

| Frequency coefficients | Np | 2280 | 2200 | 2160 | 2280 | 2100 | 2200 | |

| N1 | 1671 | 1613 | 1583 | 1671 | 1539 | 1613 | ||

| N3 | 1950 | 1900 | 1875 | 1950 | 1850 | 1850 | ||

| Nt | 2250 | 2200 | 2200 | 2300 | 2200 | 2200 | ||

| Elastic compliance coefficient | Se11 | 10-12m2/n | 11.8 | 12.7 | 13.2 | 11.6 | 14 | 13.2 |

| Machanical quality factor | Qm | 1000 | 800 | 600 | 1200 | 400 | 2200 | |

| Dielectric loss factor | Tg δ | % | 0.3 | 0.4 | 0.5 | 0.3 | 0.6 | 0.5 |

| Density | ρ | g/cm3 | 7.5 | 7.5 | 7.5 | 7.6 | 7.5 | 7.5 |

| Curie Temperature | Tc | °C | 320 | 320 | 320 | 310 | 310 | 310 |

| Young's modulus | YE11 | <109N/m2 | 85 | 79 | 76 | 86 | 71 | 76 |

| Poison Ratio | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.33 |

Soft PZT

High sensitivity or "soft" ceramics feature high sensitivity and permittivity, but under high drive conditions are susceptible to self heating beyond their operating temperature range . These materials are used in various pick-ups and sensors, low-power motor-type transducers, receivers, and low power generators.

PZT-5 Series

The PZT-5 series materials are all [soft". They range in Curie temperatures from 165°C to 350°C. All these materials have been optimized for charge constants or coupling coefficients for specific applications. PZT-5 series is often used as the receiver or generator element in hydrophones, accelerometers, and vibration sensors. PZT-5 Series is a lead zirconate titanate with a high sensitivity, permittivity, and time stability. PZT5H series is used in sensitive receivers and applications requiring fine movement control. It has been used in a wide range of applications from hydrophones to ink jet printers. PZT5H Series provides extremely high permittivity, coupling, and piezoelectric constant.

The typical value of "Soft PZT" ceramic performance

"Soft" PZT materials

Properties

PSnN-5

PLiS-51

PZT-51

PZT-52

PZT-53

PZT-5H

PZT-5X

Dielectric Constant

ɛTr3

1600

2000

2200

2400

2600

3200

4500

Coupling factor

KP

0.6

0.62

0.62

0.63

0.64

0.68

0.7

K31

0.35

0.35

0.35

0.35

0.36

0.38

0.4

K33

0.68

0.7

0.68

0.7

0.7

0.76

0.77

Kt

0.5

0.52

0.5

0.5

0.5

0.52

0.53

Piezoelectric coefficient

d31

10-12m/v

-170

-197

-186

-204

-227

-275

-300

d33

10-12m/v

400

450

500

520

550

620

750

g31

10-3vm/n

-12

-11.1

-9.6

-9.8

-9.9

-9.7

-7.5

g33

10-3vm/n

28

25.4

25.6

24.5

23.9

22

18.8

Frequency coefficients

Np

2000

1920

1980

1980

1960

1900

1960

N1

1466

1407

1451

1451

1437

1393

1437

N3

1825

1925

1900

1900

1755

1550

1800

Nt

2100

2100

2150

2150

2150

2100

2200

Elastic compliance coefficient

Se11

10-12m2/n

16.6

18

16.7

17

17.4

18

19

Machanical quality factor

Qm

85

80

80

75

75

70

65

Dielectric loss factor

Tg δ

%

2

2

2

2

2

2

2

Density

ρ

g/cm3

7.5

7.5

7.6

7.6

7.6

7.5

7.5

Curie Temperature

Tc

°C

350

345

270

270

270

230

165

Young's modulus

YE11

<109N/m2

60

56

60

59

57.5

56

53

Poison Ratio

0.36

0.36

0.36

0.36

0.36

0.36

0.39

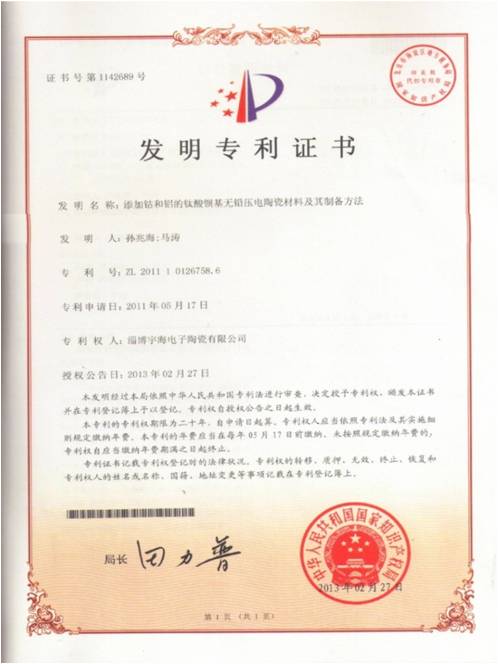

The Co-Al Co-doped Barium Titanate Lead-free Piezoelectric Ceramics was successfully developed by Yuhai company through repeated experiments. By Researching the influence of Co-Al Co-doping on the structure and properties of Barium Titanate-based piezoelectric ceramics, the formulation and preparation technology of Barium Titanate-based piezoelectric ceramics were optimized. Yuhai`s BaTiO3 was prepared by conventional solid-phase sintering method, with the piezoelectric constant d33 (>170pC/N), dielectric loss tgδ≤0.5% and mechanical coupling coefficient Kp≥0.34.

Barium titanate lead-free piezoelectric ceramics are important basic materials for the development of modern science and technology, which was widely used in the manufacture of ultrasonic transducers, underwater acoustic transducers, electroacoustic transducers, ceramic filters, ceramic transformers, ceramic frequency discriminators, high voltage generators, infrared detectors, surface acoustic wave devices, electro-optic devices, ignition and detonation devices, and piezoelectric gyroscope and so on.

Application: military, ocean, fishery, scientific research, mine detection, daily life and other fields.

China Patent No.: ZL 2011 1 0126758.6

Material: Lead-free Barium Titanate Piezoelectric Material with Addition of Cobalt and Aluminum

Typical value of lead free piezoelectric ceramic BaTiO3

| Lead free piezo material BaTiO3 | Lead-free Material | ||

| Properties | BaTiO3 | ||

| Dielectric Constant | ɛTr3 | 1260 | |

| Coupling factor | KP | 0.34 | |

| K31 | 0.196 | ||

| K33 | 0.43 | ||

| Kt | 0.32 | ||

| Piezoelectric coefficient | d31 | 10-12m/v | -60 |

| d33 | 10-12m/v | 160 | |

| g31 | 10-3vm/n | -5.4 | |

| g33 | 10-3vm/n | 14.3 | |

| Frequency coefficients | Np | 3180 | |

| N1 | 2280 | ||

| N3 | |||

| Nt | 2675 | ||

| Elastic compliance coefficient | Se11 | 10-12m2/n | 8.4 |

| Machanical quality factor | Qm | 1200 | |

| Dielectric loss factor | Tg δ | % | 0.5 |

| Density | ρ | g/cm3 | 5.6 |

| Curie Temperature | Tc | °C | 115 |

| Young's modulus | YE11 | <109N/m3 | 119 |

| Poison Ratio | 0.33 |

Klik Hier om onderzoek te sturen

Mr. Sun Zhaohai

Telefoonnummer:0086-533-4230012

Fax:

Mobiel:+8618753397607

E-mail:ceo@zbyuhai.com

Adres:No.57 Chuangye Road, Boshan Economic Development Area, Zibo, Shandong

Mobiele website

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.